Vintage Veloce

pro rider

I wanted to check the spoke torque.

I wanted to check the spoke torque.The manual suggests checking them by sound, and I have done it that way... but I decided to buy a spoke toque wrench.

I bought the RK Excel wrench, but found the Svart uses an unusual spoke nipple size, about 6.8mm.

So I took the next smaller size and carefully filed it to fit perfectly.

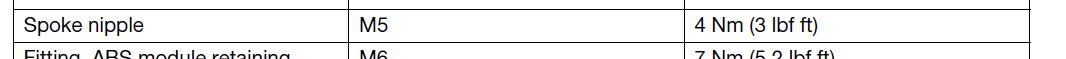

Next... what is the spec for the spoke torque? I couldn't find it anywhere.

As the bike is fairly new, I decided to go around, slowly raising the wrench's torque setting until I hit on a number that seemed to be where most of the spokes were set already. I didn't loosen any spokes, I just kept raising the torque until the looser spokes tightened a bit and the already tight spokes clicked the wrench without moving.

I then checked that the wheels were still true by spinning them with a pointer on the rim edge.

Here is what I came up with, on my particular wrench (wrenches my not be calibrated the same).

Note this is with the wheel off the ground and unloaded! Having weight on the wheel will put tension on the spokes unevenly, don't do that.

This is on my 2020 Svartpilen 401:

Front, both sides: 4 Nm

Rear, right side (disc) 4 Nm

Rear, left side (sprocket) 3 Nm

I'm assuming the Rear left side is lower torque because those spokes are shorter.

But note, I just found these number empirically.

Has anyone found an actual spec anywhere for the spoke torques?