You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Custom tail tidy

- Thread starter miki

- Start date

vaïk

contributing rider

And only 12 points on my driver's license...130km/h?!? OK, you must definitely have some Viking genes!?!

Not for an extended long period of time, but 200km/h is quite "normal" here; even with the 801 without any wind protection; welcome to Germany...

toast449

top rider

Well Tom lost a plate with the aluminum mount failing from a 1200 SDR. Good luck, hope it doesn't come off and damage someone's car or worse.

Yes, but the 1290 plate broke because of a design-flaw / fabrication failure; with the quite thick printed base plate I would assume that it should work quite similar to the 3mm aluminum base plate,Well Tom lost a plate with the aluminum mount failing from a 1200 SDR. Good luck, hope it doesn't come off and damage someone's car or worse.

Last edited:

3D prints can handle immense forces when engineered correctly.There is no way I would trust a plastic base plate for what is effectively a sail attached to the back of a hot, vibrating mass moving at 100 kph.

In Vaiks case there isnt much to be done. I would add a thin piece of aluminum or a layer of carbon fiber in between the base plate and the motorcycle, but thats about it of what you can do to strengthen the part.

vaïk

contributing rider

Okay! The project is risky, but still less risky than driving at 200 km/h on the motorway!

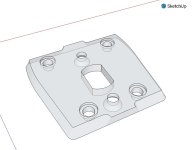

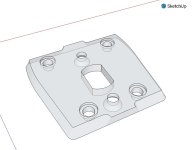

The base and angle corrector are printed in ASA.

In the end, I'm not going to recook them because with the reduction I'll lose the screw placement.

If I have time to paint them this week, then maybe I'll have time to do a road test this weekend!

For those who want it, the STL or the SKP is available upon request.

The base and angle corrector are printed in ASA.

In the end, I'm not going to recook them because with the reduction I'll lose the screw placement.

If I have time to paint them this week, then maybe I'll have time to do a road test this weekend!

For those who want it, the STL or the SKP is available upon request.

Last edited:

The two holes to attach the aluminum mount might indeed be a weak link; if it would be me, I would add two slightly recessed big washers (made from steel) underneath the countersunk screws.

Edit: the head of a standard M6 countersunk screw is 12mm; the inner diameter of a M10 washer is 10,5mm; it should work fine.

Edit: the head of a standard M6 countersunk screw is 12mm; the inner diameter of a M10 washer is 10,5mm; it should work fine.

Last edited: